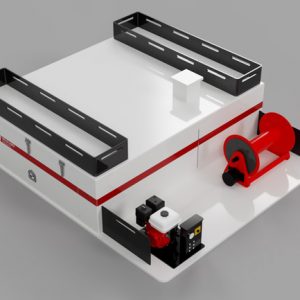

Integrated Slip-On Module 350 gal High Cargo Capacity

$23,520.00 – $26,160.00

Easy to mount system with everything needed to transform your existing Class 3, 4 or 5 Medium truck equipped with an 8 to 9-foot flatbed, into a high-performance type 6 Fire Engine. Features an Integrated design: water tank, high capacity cargo compartments, and pump platform are all in one piece. Removable high-pressure fire-fighting pump and controls, class A foam system, and electric rewind hose reel.

Complies with NFPA 1906 requirements for slip-on fire-fighting modules and NWCG specifications for, and 6 Wildland Fire Engine.

For shipping/delivery and payment options, contact us.

Please contact us before placing your order.

Specifications

- Water Tank: 300 to 350 gallons (US) capacity. 100% polypropylene construction with double-sided extrusion welds throughout. Structural baffling system, internal 2” low level suction strainer, and removable lid with welded fill tower with integrated strainer. Water level sight-glass built into rear wall of tank (Figure 1). 1.5” expansion drain plug.

- Compartments: Two high capacity 29.5 cubic foot compartments, with two polypropylene door each. Stainless steel 3 point, keyed, T-handle latch system, stainless-steel heavy-duty hinges, and 2 gas struts per door.

- Cargo Racks: Two 13.5 square foot over compartment areas. Other configurations available upon request.

- Foam Cell: Bolt-on design, 10 gallons (US), with internal ¾” foot valve/low level strainer and integral filler strainer vent cap (Figure 1).

- Anchoring System: The integrated slip-on module attaches directly to the existing flatbed using 12-1/2” and 8-3/8” stainless steel bolts. Four 3/8” stainless steel lifting eyes are located on each corner of the tank to aid with installation.

- Weight: 650 pounds, not including pump or hose reel.

- Pump: WILDLAND PRODUCTS PRO 250 PUMP (Figure 2). Speed increaser style, single-stage centrifugal pump. 250 PSI max/110 GPM. 2” suction and 1.5” discharge ports. Features aluminum alloy construction, bronze impeller, and carbon ceramic seals. Powered by a 14 HP high torque electric start Kohler Gasoline engine equipped with 4 stage air filtration system, integral 1.77 Gallon fuel tank, and backup recoil start (Figure 4). (WILDLAND PRODUCTS PRO 300 PUMP as optional upgrade.)

- Discharge Manifold: Lightweight, modular, hard-anodized aluminum manifold with brass ball valves. Comes standard with 1.5” NH discharge, 1” return/tank fill line, and 1” hose reel valve (Figure 3). Other configurations and swing-out valves available upon request.

- Suction: 3-way T port stainless steel 2” valve (Figure 3).

- Primer: Electric one-button system. Features an electric solenoid valve in conjunction with a Pentair electric diaphragm 3 GPM pump.

- Foam Proportioner: Scotty 4171 around the pump class A foam proportioner. Concentration range 0.15% to 3%. (Trident FOAMATE optional upgrade.)

- Control Panel: Compact design, fabricated in polypropylene and attached to the pump module mounting pad. Contains the following: fluid filled pressure gauge, throttle control, choke, low pressure protection system, primer, lights, hose reel rewind, and foam proportioner (Figure 6). Control panel design may vary.

- Pump Module Mounting Pad: Removable, fabricated polypropylene. All pump system components are attached to this structure; bolts onto the slip-on pump platform using eight 3/8” stainless steel bolts (figure 4).

- Couplings: Hard anodized aluminum expanded ring rocker lug fire grade couplings used throughout (Figure 3).

- Hose Reel: REELCRAFT series 30000 with 175 feet of 3/4” semi-rigid hose. Electric rewind and roller guide standard. (1” hose reel also available.)

- Electrical Connections: 4 AWG with 50-amp circuit breaker from battery box to pump module. 10 AWG from pump module to hose reel. Quick connectors in both circuits for quick removal of pump module (Figure 6).

Additional information

| Pump Type | Included Pump Only, Wildland Products Pro 300 pump |

|---|---|

| Foam System | Included Foam System Only, Remove Foam System, Trident FoamFlo |